I had to inform the owner.

As you both know I only have your best interest at heart. I need to tell you about a flaw in the design of the “boxed” frame of every Mark II ever made. I only suspected this from 40 years of experience in the light pole maintenance business. Light pole are falling all over the world from rust eating the steel out from the inside. The very thing is happening on all Mark IIs.

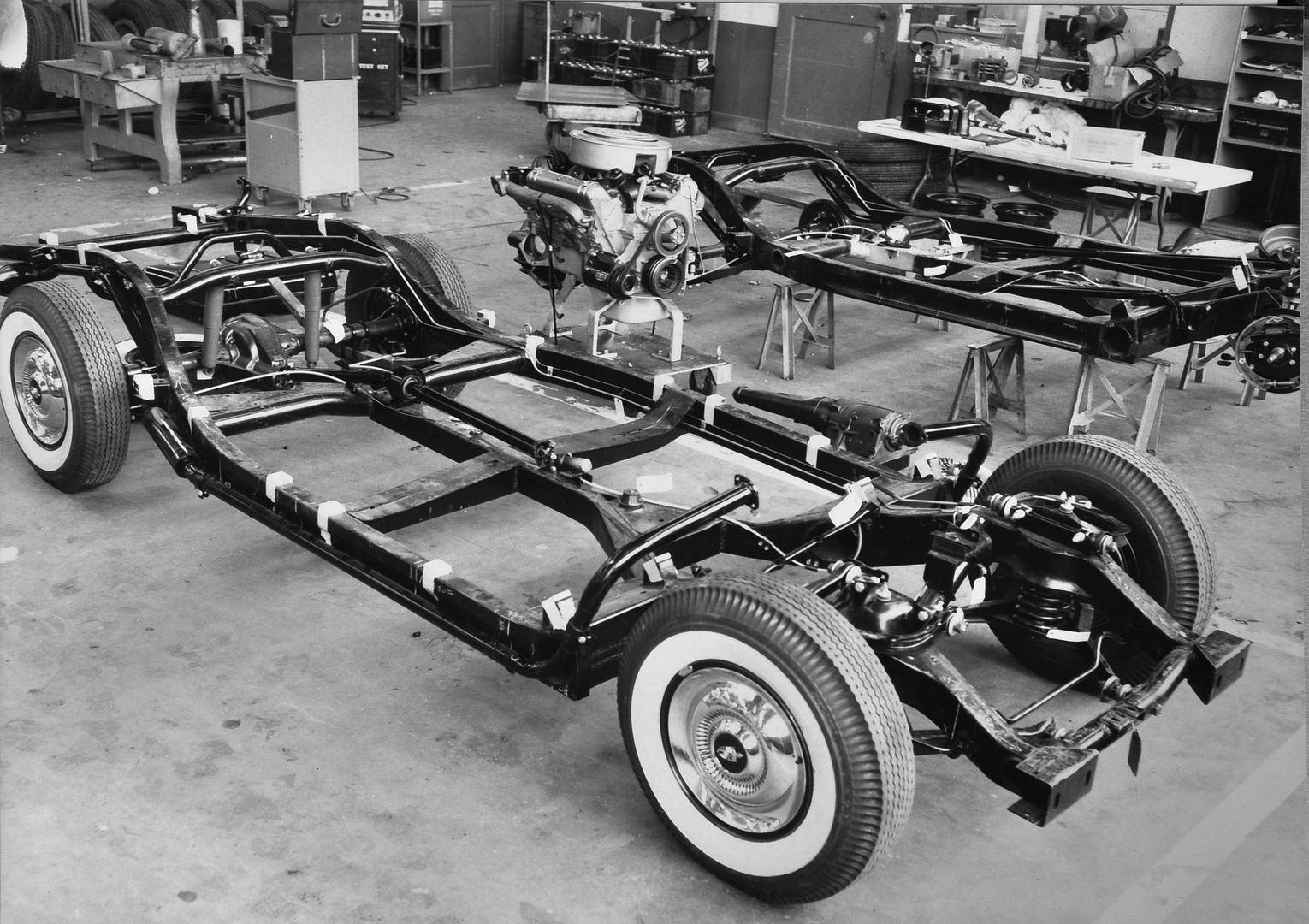

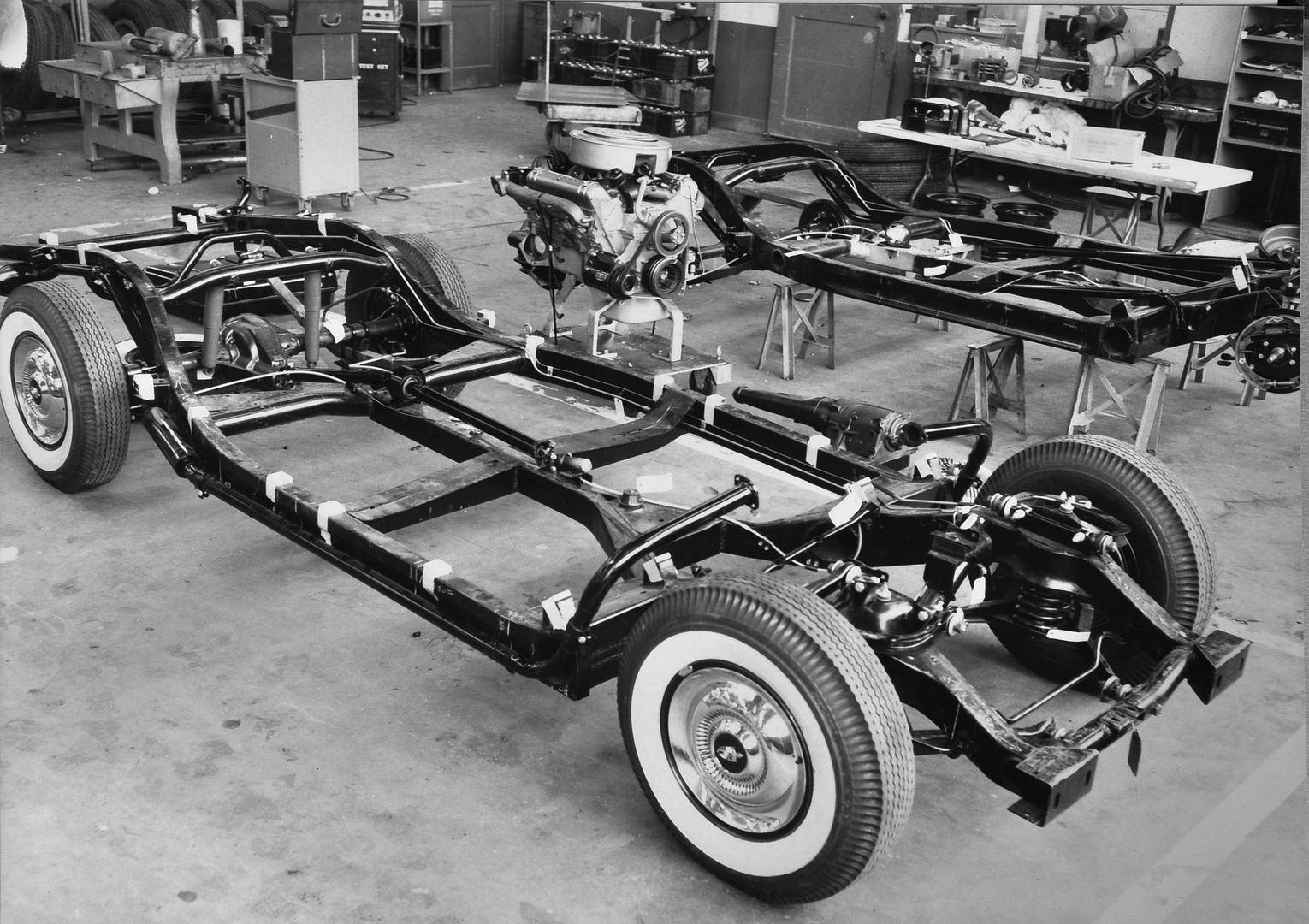

Most steel light poles were never painted on the inside and started rusting the day they’re made. The outsides were cleaned and painted, but, like the Mark II chassis, wasn’t dipped, so rust flakes kept falling to the bottom of the rectangular frame rail that runs the length of the car between the tires. The bumpers attach directly to the frame rails, front and rear.

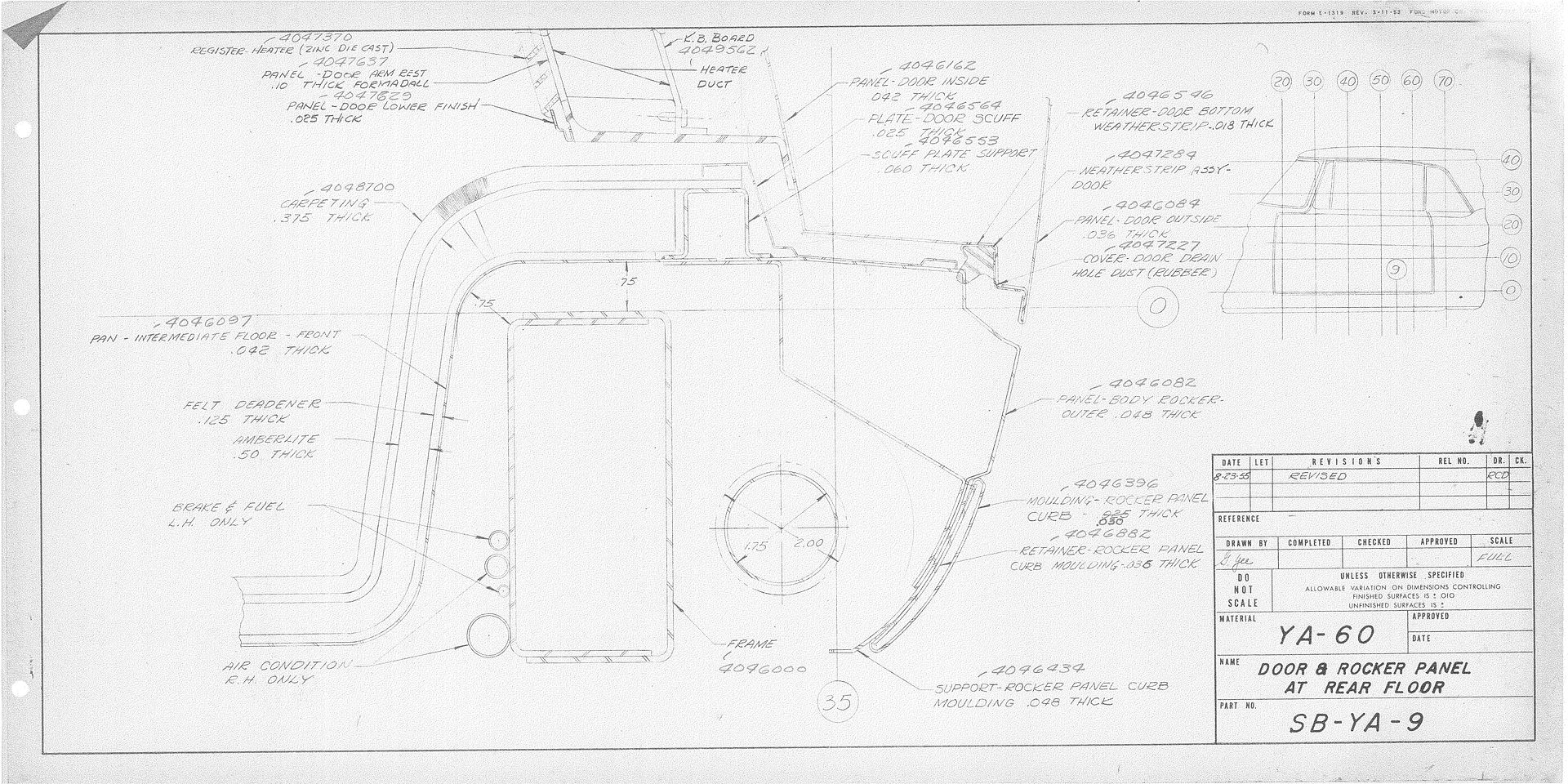

The frame rails are put together with two pieces of sheetmetal that are [-shaped and ]-shaped and fit inside each other creating a “boxed” frame that’s rectangular, about 2.5” wide and 5” tall, one on each side. A design flaw I’ve found only affects the horizontal sections between both wheels on both sides.

By welding [ and ] together that created an overlap of 1/8” stamped steel. They used stitch-welding, 1" of weld for 3 “ of frame rail length. If you used continuous welds the frame would warp from heat. They never thought these would be around more than 10 years and gave no thought to drainage or longevity. Rain splash, and dew, kept the inside of the steel wet, especially if the car was parked after driving in the rain. The frame has plenty of holes to let it dry out at speed, but has no drain holes to let water out. The frame is held in position at jig holes for welding that let water and mice in, but no drainage to let water or mouse pee out so the rust blooms start pushing apart the frame layers, feeding the building of iron oxide (rust) in the process.

This is looking up through the bottom of the frame where I pointed out to you what might be surface rust, but it’s not. It’s rust that’s eaten through from the topside. I drilled a drainage hole near that exposed rust I burned up 2 drill bits as rust (Iron Oxide) is much harder than steel. You should be able to discern a shiny ring of steel at the top and one at the bottom of the hole. The original steel has been reduced by 75% from 1/8” to maybe 1/32”. The top of the frame rails and the sides are largely unaffected, just where water sat in the bottom of the frame.

Is the car drivable, yes. Is it crashable, no, but it wasn’t very crash-friendly to begin with. Is there anything that can be done about the damage? There is a treatment that seeps into the rust and stabilizes it, but nothing will restore the original integrity. In a way, it could be a godsend in a crash as the tearing metal would absorb some energy before it getting to you. The problem is that it’s not an engineered solution. Anything can go wrong. I would be of no hope in a side-impact, There is nothing inside the door but air and window glass. In a front impact the frame could buckle, forcing the doors closed.

I would start driving the car with great awareness of your surroundings. Better to be stuck at a light than go through an intersection too late. The way it is it will likely outlive us, but had I not made you aware of my findings, I would be remiss, both as your friend and mechanic.

Barry

Last edited by Barry Wolk; 06-27-2022 at 06:32 AM.

Barry Wolk

Farmington Hills, MI

C5681126

Reply With Quote

Reply With Quote